Lithium Battery BMS Requirement

BMS Introduction

Battery Management System (BMS) is any electronic device that manages a rechargeable battery (cell or battery pack), such as by monitoring its state, calculating secondary data, reporting that data, protecting it, controlling its environment, and / or balancing it.

BMS requirement for LIDL projects

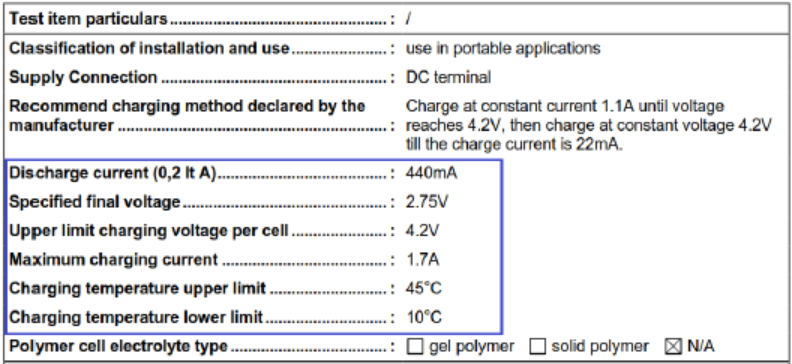

The Lithium battery pack has IEC 62133 report.

Additional inquiry from LIDI supplier:

1. Battery cells must be decoupled from the circuit to counteract deep discharge.

2. Round battery cells must have an elevated positive terminal.

Lithium Battery BMS Requirement

IEC 60335-1 Annex B ED5.2 and 19.11.3

Appliances are supplied at rated voltage for 168 h, the battery being continually charged during this period.

If the appliance incorporates a protective electronic circuit which operates to ensure compliance with Clause 19, the relevant test is repeated with a single fault simulated.

IEC 61347-2-7 ED3.2 CI.22 and 23

22 Recharging device

Low temperature operation – The battery shall be charged for 48 h or twice the charge time as declared in 7.2 with a minimum of 12 h and then discharged until the voltage indicated in Table 1 is achieved.

The recharging device shall then be operated to charge the fully discharged battery ESSS at 0,9 times the rated supply voltage and at the minimum of the declared ambient temperature range of the controlgear for a period of 24 h

During the test, all parts shall be placed within the test cabinet at its own minimum declared minimum temperature rating. Normal lighting supply failure shall then be simulated and the battery ESSS shall operate the lamp from the controlgear for the rated duration of the operation.

High temperature operation – The test of 22.1 is repeated at 0,9 times the rated operating voltage but at the maximum of the declared ambient temperature range.

Abnormal operating condition – The recharging device shall be operated at 1,1 times the rated supply voltage and the maximum of the declared ambient temperature range with the batteries ESSS disconnected and replaced by a short circuit link. The test shall continue until stable conditions are achieved or a protective device (e.g. fuse or thermal link) operates.

There shall be no emission of flames or molten material, or production of flammable gases from the recharging device.

On completion of the test period, the short circuit link shall be removed, the battery ESSS shall be reconnected and user replaceable fuse links replaced where necessary. The recharging device shall remain safe.

23 Protection against excessive discharge

Following a full charge cycle (24 h at rated voltage), the battery voltage and discharge current are measured during an emergency mode cycle to full discharge (or battery cut-off switching).

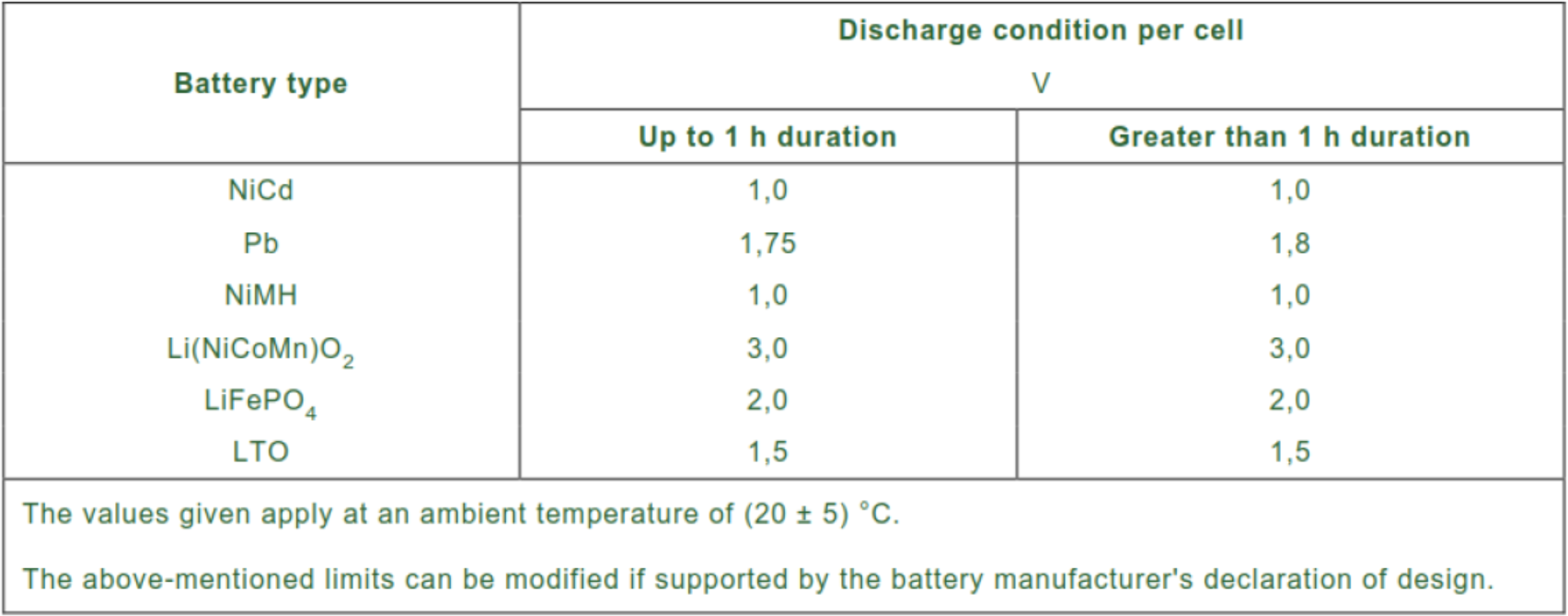

The battery voltage shall not fall below Vlow and the discharge current shall not exceed that specified. Testing is conducted at 25 °C ±2 °C.

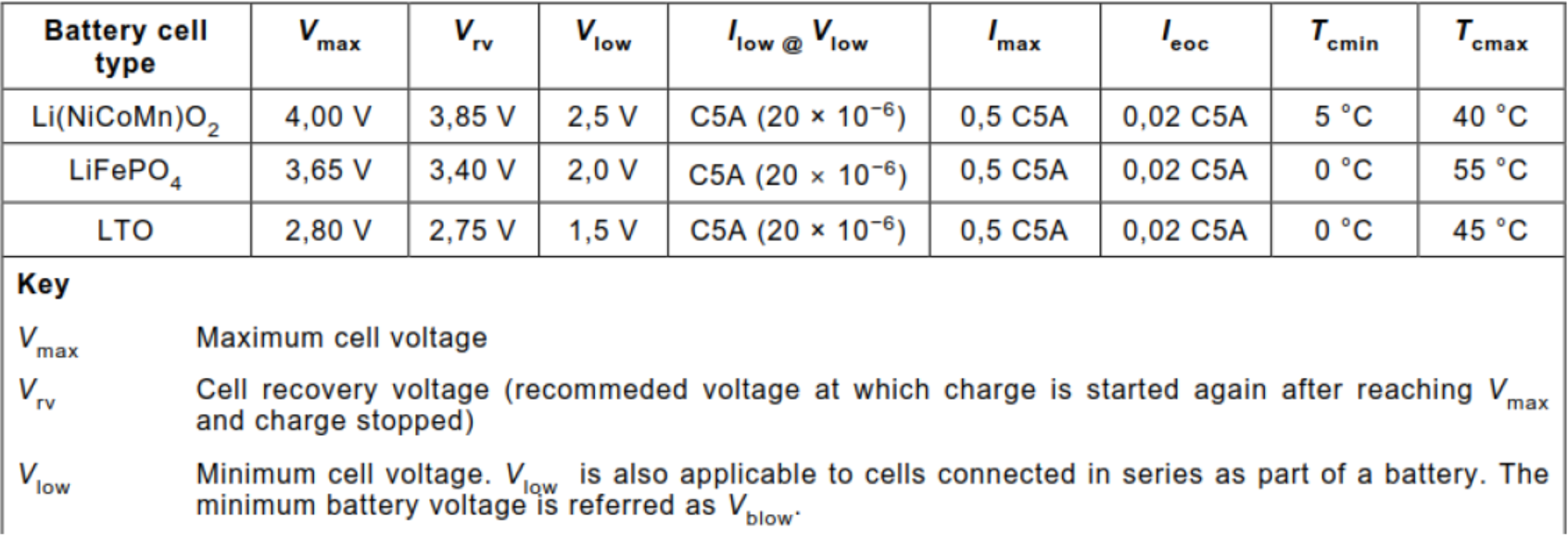

d) For Li batteries:

– Vblow = X · n where n is the number of cells in series;

If a different value is specified by the battery manufacturer in the declaration of design, this value shall be applied for X.

– I ≤ Ilow· m, where m is the number of cells in parallel,

The protection system shall prevent any further discharge of the batteries by a lamp or inverter, even where a battery voltage rise due to natural regeneration occurs, until the normal supply has been restored.